Berghof Membrane Technology GmbH

Booth number: 7-C15

www.berghofmembanes.com

About us

Berghof Membrane Technology GmbH (Berghof Membranes), part of the Berghof Group, is your leading manufacturer of tubular membranes for the filtration and separation of process streams and wastewater in a variety of industries including dairy, landfills, mining, food & beverage, chemical & pharmaceutical, and oil & gas. With over 50 years of experience and over 2,500 installed systems across the globe, Berghof Membranes prides itself on the robustness, flexibility, energy-efficiency and superior quality of its external filtration membranes and solutions. When it comes to membrane filtration, think outside the box and contact Berghof Membranes today.

Address

Arbachtalstr. 26

72800 Eningen

Germany

E-mail: info@berghofmembanes.com

Phone: +31 58 8100110

Internet: www.berghofmembanes.com

Contact person:

Amir Mahmoud

Regional Sales Manager DACH CIS & MIDDLE East

E-mail: amir.mahmoud@berghof.com

Products & Services

1. Berghof Membranes – Product & Service Overview

With over 50 years of experience and more than 2,500 installed references worldwide, Berghof Membranes is the global expert in the development and supply of tubular ultrafiltration (UF) membrane solutions for the treatment of industrial wastewater and process streams.

2. Membrane Portfolio

Our membranes are engineered for performance, durability, and flexibility across a wide range of industrial applications:

Tubular UF Membranes, with a variety of pore sizes to suit specific filtration needs.

5 mm for low-mid range TSS & high packing density

8 mm for standard-high range TSS

12.7 mm for high TSS or high viscous process solutionsBackwashable Membranes

Designed for enhanced cleaning efficiency and improved energy performance.Chemical-Resistant (CR) Membranes

Built to withstand a broader pH range when coupled to chemical precipitation for softening or brine recovery

3. Applications:

Membrane Bioreactor (MBR)

Anaerobic MBR (AnMBR)

Direct filtration · Ultrafiltration coupled to chemical precipitation · Water Softening

Ultrafiltration coupled to chemical precipitation

Solutions for:

Industrial wastewater treatment

Digestate management

Landfill Leachate treatment

Bulk Water Softening and RO brine recovery

Recovery of valuable products

Polishing for reuse

4. B-SMART® Platform

Our B-SMART® concept supports OEMs with a modular and scalable platform that includes:

Engineering Packages

Pre-Built Membrane Skids for OEMs

Advanced Control Philosophies

B-Connect® (360-degree support service combining proactive system monitoring, process optimization, expert technical guidance…)

5. B-CARE®

The B-CARE® program from Berghof Membranes is an end-to-end comprehensive program developed to support our OEM partners from the piloting and engineering phase to operational system monitoring.

Chemical Resistant Membrane Modules

History has shown that cleaning wastewater streams with chemicals that contain high pH values achieves the best results. A major disadvantage is that many membranes are not robust enough to withstand the highly concentrated alkaline detergents, resulting in wear and tear of the membrane and degradation of the membrane’s performance and service life.

With this in mind, Berghof Membranes has developed its line of robust Chemical Resistant (CR) membrane modules. The resistance to a wide variety of chemicals and pH values (2 – 12) means that our CR membranes are ideally suited for applications with high-strength wastewater or process streams.

In addition, intensive cleaning with strong alkaline (pH values 1 – 13) will not affect the quality of the CR membrane . The result is a longer service life and optimal filtration results.

Transmembrane pressure [kPa]: -60 to +600

pH range: 1 – 13

Membrane Diameters: 5, 8, 12.7 mm

Membrane area: from 2.1 up to 71.1 m2

Module diameters available: in 3, 4, 6, 8 and 10 inch

Module lengths: 1.5, 3, 4 m

Backwashable membranes modules

Traditional wastewater treatment systems rely heavily on Clean-In-Place (CIP) protocols using relatively large quantities of chemicals which are costly and require operational shut-downs. Backwashable membranes, when used in combination with the intelligent software technology by Berghof Membranes, allow the wastewater system to operate at a lower velocity, thus consuming less energy. During the backwash, in which clean water is pushed outside-in, fouling is removed from the membranes module by module. Therefore, the system continues to produce permeate during backwash because the backwash procedure is performed sequentially by the module. If backwash with permeate doesn’t eliminate fouling, the intelligent software will automatically initiate a chemical-enhanced backwash (CEB).

Transmembrane pressure [kPa]: -60 to +800

pH range: 2 – 11

Membrane Diameters: 5, 8, 12.7 mm

Membrane area: from 2.1 up to 71.1 m2

Module diameters available: in 3, 4, 6, 8 and 10 inch

Module lengths: 1.5, 3, 4 m

Hyperflux Membrane Modules

For crossflow filtration applications with high-strength wastewater, high crossflow velocity and pressure rates, our non-backwashable membranes are the ideal choices. Our membrane durability and excellent fouling resistance ensure long membrane life and optimal membrane performance.

Transmembrane pressure [kPa]: -20 to +800

pH range: 2 – 11

Membrane Diameters: 5, 8, 12.7 mm

Membrane area: from 2.1 up to 71.1 m2

Module diameters available: in 3, 4, 6, 8 and 10 inch

Module lengths: 1.5, 3, 4 m

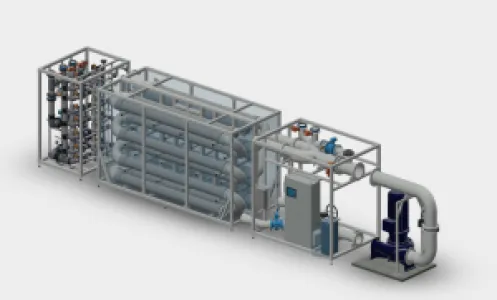

B-SMART® UF Skid

B-SMART® is a proprietary platform, designed specifically for our OEM partners that delivers complete and modular systems to solve the challenges in the treatment of industrial streams/effluent. Plant owners are looking for cost-effective and reliable solutions that can support industrial growth. Plant operators want easy-to-maintain systems that can meet strict discharge standards. B-SMART® helps OEMs to deliver both. Available in multiple configurations and with various functionalities, each B-SMART® system is expertly engineered with unique features and advantages to provide the flexibility, adaptability, and reliability you and your customers want.

Containerized UF pilot systems

Our containerized pilot units are plug-and-play and feature standardized but flexible software, allowing them to be customized to your filtration challenge. They have been designed to be flexible with the aim of coping with a broad range of wastewater characteristics and operational conditions: several membrane types, filtration parameters, and flow capacities can be very easily implemented. The pilot units of Berghof Membranes are stand-alone and easy to connect, preventing extensive capital investments required. The pilots are automated for continuous operation, with fully safe operation and online monitoring.

B-Care® - Services

The B-CARE® program from Berghof Membranes is an end-to-end comprehensive program developed to support our OEM partners from the piloting and engineering phase to operational system monitoring. Because process streams and wastewater can vary significantly, there is no typical or standard wastewater treatment solution.