MANN+HUMMEL Water & Fluid Solutions GmbH

Booth number: 7-C12

water-membrane-solutions.mann-hummel.com

About us

MANN+HUMMEL Water & Membrane Solutions is a global leading membrane manufacturer, delivering innovative solutions to meet diverse water and process needs. We offer an extensive range of membrane products, including MF, UF, NF, MBR, and RO technology, available in flat sheet, spiral-wound, tubular and hollow-fiber configurations for water and wastewater treatment as well as seawater desalination. Our solutions also cater to the food and beverage sector, biotechnology, and other ultra-pure water areas such as semiconductors.

MANN+HUMMEL is a leading global filtration expert with more than 80 years‘experience. Discover our wide range of membranes and filters for these applications—and more! Get in touch with us for the perfect filtration solution for your specific needs.

Address

Kasteler Str. 45

65203 Wiesbaden

Germany

E-mail: info.wfs@mann-hummel.com

Phone: +49 611 71187480

Internet: water-membrane-solutions.mann-hummel.com

Office 1013, Bldg. 7WA, DAFZA (Dubai Airport Free Zone)

25314 Dubai

United Arab Emirates

E-mail: imad.umer@mann-hummel.com

Phone: +971 55 3964370

Internet: water-membrane-solutions.mann-hummel.com

Contact person:

Arif Karahaliloglu

Global Sales Development Manager

E-mail: arif.karahaliloglu@mann-hummel.com

Phone: +49 173 4215271

Products & Services

We offer the widest range of membrane products, including microfiltration, ultrafiltration, nanofiltration, and reverse osmosis in flat sheet, spiral-wound, and hollow-fiber configurations, as well as MBR technology for treatment of water and wastewater.

Our water filtration systems are used for water and wastewater treatment in municipal and industrial applications. In this way, scarce freshwater resources are efficiently utilized and recycled. Special applications in the food sector, biotechnology, or other ultra-pure water areas such as microelectronics are further areas of application. With robust private label and customization options, we provide solutions uniquely designed for customer applications.

RO/NF spiral wound membranes

MANN+HUMMEL Water & Membrane Solution offers spiral wound membranes designed to meet specific customer requirements, delivering high-performance results.

RO membranes are typically made of thin-film composite (TFC) materials, and can be used for:

- Boiler feedwater

- Industrial process water

- Water re-use

- Polishing effluent from MBR or UF

- Desalination

NF membranes, depending on the modules characteristics, offer a selective rejection of divalent and polyvalent ions while permitting the monovalent ions to pass through membranes. They can be used for:

- Water softening

- Removal of certain contaminants

RO /NF membranes are available in 2.5”, 4” and 8” spiral wound design but also in several other size and configuration.

PureULTRA II

PureULTRA II UF modules are constructed using highly hydrophilic modified PVDF hollow fiber membrane with a tight nominal pore size of 0.025 micron. The outside-in flow configuration contributes to easier cleaning as it keeps the solids, pathogens, and other foulants on the outside of the fibers. The fiber is designed to handle most feed water sources and tolerate solids loadings while operating within an optimal flux range.

PureULTRA II modules are used for:

- RO pretreatment

- Surface water treatment (plant influent)

- Water reuse

- Tertiary wastewater treatment

- Seawater treatment

BIO-CEL MBR series

BIO-CEL MBR is a cost-effective and scalable solution for meeting challenging effluent requirements for municipal and industrial wastewater treatment.

It creates a cleaner, higher quality effluent than conventional wastewater treatment systems, using up to two times smaller overall footprint due to its high packing density.

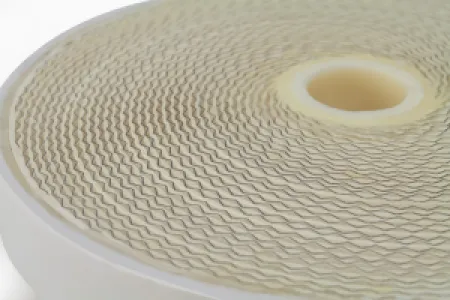

The BIO-CEL series is built upon our unique, patented self-healing laminate technology – a proven innovation that has been delivering reliable performance for over 15 years. This revolutionary technology addresses the critical challenges faced by traditional MBR applications, such as membrane durability and fouling, among other key benefits:

- Reliable filtration quality

- Enhanced fouling resistance

- Reduced cleaning frequency

- Minimized energy demand and downtime

- Optimized TCO (total cost of ownership)

iSep 500+

iSep 500+ UF modules offer compact, efficient treatment for high-fouling and variable-quality water sources. With an integrated tank design and vacuum-driven spiral-wound membrane, iSep 500+ handles challenging feedwaters such as industrial effluents, river water, and produced water with ease.

Featuring a hydrophilic 0.03 μm PVDF/PES membrane, the system removes suspended solids, oil & grease, and turbidity while delivering consistent, high-quality permeate. Internal aeration and backwash features reduce chemical use and fouling, enabling stable operation even under heavy solids loading—without the need for extensive pre-treatment or large tanks.

TurboClean

When it comes to sanitary membrane elements, there is a stronger choice for processors of dairy products, sweeteners, beer and wine, pharmaceutical products, proteins, and many other process streams. TurboClean elements feature a rugged polypropylene shell that results in a stronger, more rigid, and durable element ideal for the most challenging process applications. These elements are available with RO, NF, UF, and MF membrane types.

Their main features are:

- Enhanced Water & Energy Savings

- Most Durable Sanitary Element

- Higher Productivity

- Easiest Installation & Maintenance

- Most Effective Cleaning

TurboClean elements are used in a wide variety of process applications, including:

- Milk and Cheese Whey Processing

- Dextrose Purification

- Blood Plasma Demineralization

- Sugar Concentration

- Beer and Wine Processing

- Protein Concentration

- Antibiotic Purification and Concentration

- Clarification of Corn Syrup

- Egg White Concentration

- And many more…

Trisep DS Sanitary Elements

TRISEP DS spiral-wound sanitary elements were engineered in Germany and have been on the market for several decades. Through a strong focus on continual improvement and MANN+HUMMEL’s operational excellence in manufacturing, TRISEP DS is engineered to sustain product performance via a robust construction built with state-of-the-art technology, resulting in a long operating life.

Our sanitary elements are designed and manufactured to fit in your vessel, allowing some bypass flow around the product and eliminating stagnant zones that could lead to potential contamination and bacterial growth.

These elements are used for food, beverage, and dairy applications and have a long history of outstanding stable field performance.

The key applications are as follows:

- Milk and cheese whey processing

- Dextrose purification

- Blood plasma demineralization

- Sugar concentration

- Beer and wine processing

- Protein concentration

- Antibiotic purification and concentration

- Corn syrup clarification

- Egg white concentration

- Fruit juice processing

- Gelatin processing

- And many more..

FILTER Line - Prefilters

The FILTER Line delivers robust, efficient pretreatment to safeguard downstream membrane processes like UF and RO. Designed for diverse feedwaters, from surface and brackish to wastewater and industrial effluents, it ensures optimal membrane performance and longevity.

The FILTER Line includes:

- Cyclon Filters

- Strainers

- Self-Cleaning Filters

- Bag Filters

- Cartridge Filters

- Private labeling options are available