ProMinent GmbH

Booth number: 7-C20

www.prominent.com

About us

The ProMinent Group is a manufacturer of components and systems for metering as well as a reliable solution partner for water treatment.

ProMinent offers practical solutions for various industries through innovative products, a distinctive and long-term understanding of processes and strong application orientation. With this, ProMinent supports its customers worldwide in terms of safety, efficiency and environmental protection.

The Group is headquartered in Heidelberg, Germany. More than 2,800 employees in about 50 own sales and service companies as well as 11 production sites work hard to provide individual solutions and high-quality services to ProMinent customers in about 100 countries.

The ProMinent Group provides solutions for metering, water treatment and disinfection, measuring and control as well as digital fluid management for the following industries: Chemical industry, industrial and municipal water treatment, food and beverage industry, treatment of swimming pool water, oil and gas industry and process industry.

The extensive product portfolio consists of metering and process pumps, peristaltic pumps, measuring and control technology and sensors to manage and meter fluids as well as metering systems for water treatment. For this purpose ProMinent provides all common systems, such as chlorine dioxide plants, electrolysis systems, UV systems, ozone systems as well as systems for membrane filtration.

In order to be a long-term partner for its customers, the Group is investing constantly both in product innovations as well as in state-of-the-art manufacturing processes and a high level in-house production. 11 worldwide production facilities consistently guarantee high quality, flexibility and delivery reliability.

More detailed information is available at www.prominent.com

Address

Im Schuhmachergewann 5–11

69123 Heidelberg

Germany

E-mail: info@prominent.com

Phone: +49 622 18420

Internet: www.prominent.com

Sharjah Airport Free Zone

Building M1-05

P.O. Box 8090 Sharjah

United Arab Emirates

E-mail: alaqubawy.mamdouh@prominent.com

Phone: +971 50 6330780

Internet: www.prominent.com

Contact person:

Mamdouh Alaqubawy

Managing Director

E-mail: alaqubawy.mamdouh@prominent.com

Phone: Mobile: +971 50 6330780

Products & Services

Metering Pumps

Large choice of types, wide range of capacities: from a few US fluid ounce (millilitres), e.g. for laboratory use, to 10,566 gallons (40,000 litres) per hour, e.g. for use in food & beverage production.

The technologies in detail:

Diaphragm metering pumps (mechanically deflected diaphragm)

Hydraulic diaphragm metering pumps (hydraulically deflected diaphragm)

Plunger metering pumps

Peristaltic pumps

Classification by pump drive:

Solenoid metering pumps

Motor-driven metering pumps

Measuring, control and sensor technology

The complete solution for your processes

ProMinent manufactures components and systems for metering technology, is a reliable solutions partner for water treatment and with DULCONNEX, provides a cloud-based digital fluid management solution. Using optimised controllers, ProMinent is able to reliably monitor and control processes in public and industrial water treatment. The product range is accompanied by sensors, developed and produced in-house, for the most common measurement parameters, such as chlorine and pH. Every year, more than 150,000 sensors of the highest quality standards are manufactured at ProMinent sites. This makes ProMinent a complete solutions provider for the optimum metering of liquids, from reliable pump capacity and the correct measurement of all relevant parameters to precise process control.

Ozone Systems

Strong and high-performing

ProMinent ozone systems are used for the treatment of potable water and waste water, water in the food and beverage industry, pool water, aquarium and pool water in zoos, and cooling and process water.

Disinfection and oxidation

As the most powerful oxidising agent that can be used in water treatment, ozone is particularly well suited to removing hazardous substances, dyes, odours and flavour additives. Alongside oxidation, ozone also delivers effective disinfection. Significantly fewer environmentally harmful by-products result from the generation and use of ozone than with other comparable oxidants and disinfectants. Because of its high reactivity, ozone decomposes back into its original oxygen form in water in a matter of minutes.

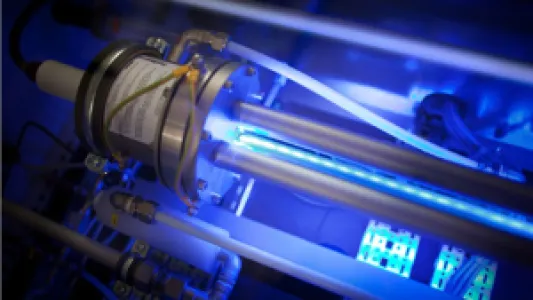

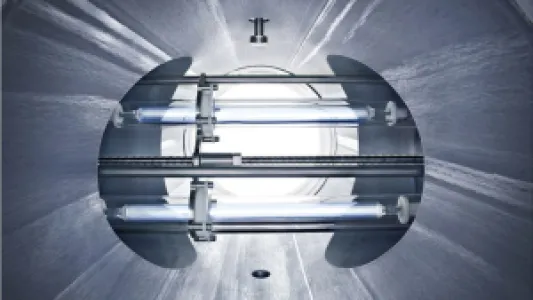

UV Systems

The UV-system DULCODES LP covers the whole range of process water desinfection in all food & baverage applications.

The UV system DULCODES LP TL for syrup disinfection declares war on heat-resistant germs. In instances when standard heat pasteurisation isn't up to the job, UV light provides a very quick and efficient form of disinfection without the need for heat.

Chlorine dioxide

Chlorine dioxide

This agent disinfects regardless of the pH. It has a very good sustained-release effect and remains active in the pipes for anything from many hours to several days. With chlorine dioxide it is even possible to treat entire water systems against legionella because it reliably breaks down biofilms in pipework and tanks.

Stable, safe, clean

The disinfecting power of chlorine dioxide is always able to develop in full because it does not react with ammonia or ammonium. By contrast, the chlorination of water can produce chlorophenols and other strongly smelling compounds. This is not the case with chlorine dioxide. Trihalomethanes (THMs) and other chlorinated hydrocarbons are also not formed.

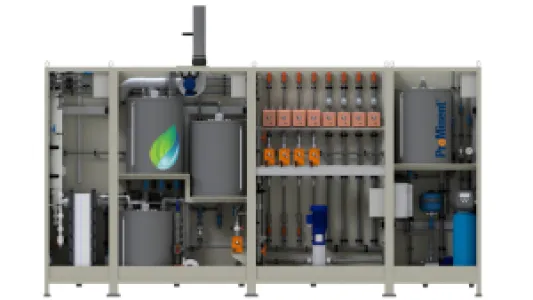

Electrolysis Systems

No chemicals required

What a great idea: no chemicals to be transported and no need to store and handle hazardous substances. Instead: sophisticated systems use harmless sodium chloride – ordinary salt – to produce chlorine, hydrogen and sodium hydroxide solution.

It's really very simple

Electrolysis is an economically viable and technically perfected alternative to the metering of sodium hypochlorite or other disinfectants. The chlorine generated from sodium chloride can either be metered into the water directly as hypochlorous acid (HOCl) or temporarily stored with the sodium hydroxide solution generated in the form of sodium hypochlorite solution (NaOCl).

Reassuring to know

There is absolutely no need to store, transport or handle hazardous chemicals when using a ProMinent electrolysis system. You can generate chlorine and perform pH corrections with one single system (CHLORINSITU V Plus / CHLORINSITU IV compact). ProMinent electrolysis systems are designed as negative pressure systems – maximum operating safety comes as standard.

Measuring and control instruments

Tailored to the job in hand

Measuring and control instruments from ProMinent are adapted to the relevant application. They are available in different performance classes and can be integrated in every process environment.

Measure and control

From simple measurement signal conversion tasks for transmission to a central control unit to calibratable units with measured value displays through to specialist controllers for complex, application-specific control tasks in various industries, ProMinent offers complete product ranges.

DULCONNEX

DULCONNEX - ProMinent’s cloud-based IIoT solution that supports you in your daily digital fluid management work. This IIoT solution comprises various components, which can be used individually or in combination with one another. Controllers be easily integrated.

Bus systems

The controllers can be connected to the control level with ease using a bus system. Various bus systems, such as PROFIBUS-DP, PROFINET and Modbus RTU are available for this purpose.

We also supply complete solutions

Anyone can sell you components. We also offer fully assembled measuring points for some measured values. To make sure you can keep using your measuring point for a long time to come, ProMinent has a wide range of accessories and spare parts. And of course, our experts are always here to help too.

Hydraulic Diaphragm Metering Pumps

Pressure and back pressure

High pressures are no problem in metering systems as long as there is something to counter them. ProMinent hydraulic diaphragm metering pumps therefore use a hydraulic fluid to create back pressure. The benefits this brings to the diaphragms become evident very quickly.

The industries in which ProMinent’s hydraulics technology is used:

Oil/gas production (onshore/offshore)

Refineries

Chemical / petrochemical industry

Pharmaceuticals & cosmetics

Food production

Packaging industry (bottling pumps)

What you can expect

The pumps run. They do this well and for a long time. Your hydraulic control is very precise and requires only minimal maintenance. The diaphragms are durable and provide consistently accurate metering. The technology also offers a very high standard of safety: there is a pressure relief valve in the hydraulic end as protection against overload. The multi-layer diaphragms are equipped with a diaphragm rupture warning system as standard. So you can be sure that the feed chemicals cannot mix with the hydraulic oil.

Plunger Metering Pumps

Plungers are synonymous with accurate metering

The heart of the liquid end in a plunger metering pump is a high-resistance plunger made from coated stainless steel. As soon as the plunger is moved into the dosing head, the suction valve closes and the feed chemical flows out of the dosing head through a discharge valve. When the plunger moves in the opposite direction, the discharge valve closes due to the negative pressure in the dosing head. Fresh feed chemical flows through the suction valve into the dosing head.

The versatile solution for all industries

ProMinent plunger metering pumps can be found in oil and gas production (onshore/offshore), refineries, the chemical / petrochemical industry, the pharmaceutical, cosmetics and food production industries, and as bottling pumps in the packaging industry. Can't find your industry? Contact us and we'll find the right pump for your application.

Pump Guide

The choice of pumps is huge: 80 industries, 100,000 products and infinite applications. To make it easy to find your ideal metering pump, ProMinent designed the Pump Guide. In just a few clicks you will find a selection of suitable models.

Here’s how it works

First enter the pump capacity and back pressure. The Pump Guide will then show you all the metering pumps that match your criteria. You can choose between list view and detail view. The database contains all solenoid metering pumps, motor-driven metering pumps, process metering pumps and peristaltic pumps from ProMinent. They are divided into more than 30 different product ranges.

Exactly the right pump

Narrow down your search by clicking on different selection criteria. Do you have a specific industry, operating mode, medium or viscosity in mind? Or maybe you need a pump for zones at risk of explosion? The Pump Guide will take you to the pump you need in just a few clicks.